AGAGE uses gas chromatography (GC) with electron-capture detection (ECD), flame-ionization detection (FID), and (at two of the stations) mercuric oxide reduction detection (MRD) to measure five biogenic/anthropogenic gases (methane, nitrous oxide, and chloroform at all sites; carbon monoxide and hydrogen at Mace Head and Cape Grim only), and five anthropogenic gases (CFC-11, CFC-12, CFC-113, methyl chloroform, and carbon tetrachloride) 36 times per day.

The list of gases measured with these "GC-multidetector" systems includes the major chlorofluorocarbons restricted by the Montreal Protocol and the current major long-lived non-CO2 greenhouse gases.

Compounds measured by AGAGE GC-MD instrument

Biogenic/Anthropogenic Gases

| Methane | CH4 |

| Nitrous Oxide | N2O |

| Chloroform | CHCl3 |

| Carbon Monoxide | CO |

| Hydrogen | H2 |

Anthropogenic Gases

| CFC-11 | CCl3F |

| CFC-12 | CCl2F2 |

| CFC-113 | CCl2FCClF2 |

| Methyl Chloroform | CH3CCl3 |

| Carbon Tetrachloride | CCl4 |

AGAGE GC-ECD/FID/MRD

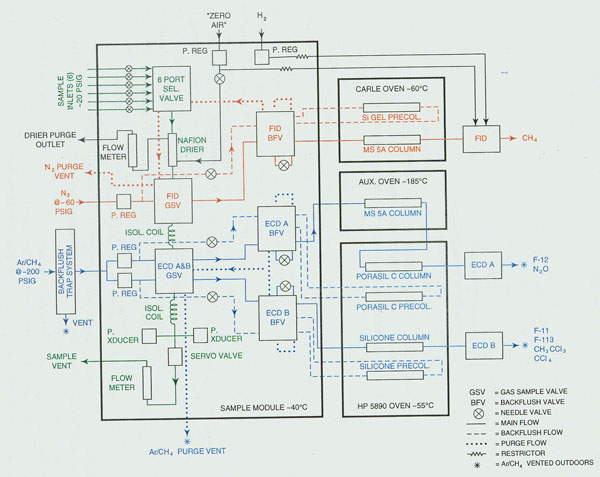

The gas chromatographic flow scheme for the AGAGE GC-ECD/FID system is shown in Figure 1. The heart of the system is a custom-built thermostatted (40°C) gas sampling module containing all the system's flow control, gas sampling, and column switching components. A Hewlett-Packard 5890 (Series II) gas chromatograph provides a column oven and two electron capture detectors (ECDs) with electrometers. A custom-made auxiliary column oven is mounted in the HP 5890 gas chromatograph (GC). This instrument is used to measure the halocarbons and N2O. A Carle AGC-211 GC provides a third column oven and a flame ionization detector (FID) used to measure CH4.

The sample module is fitted with six electrically actuated Valco gas chromatographic valves, each fitted with purge housings to avoid contamination by ambient trace gases. Porter instrument pressure regulators and Nupro flow control needle valves are all mounted inside the sample module to minimize their drift due to temperature variations.

The six pressurized sample inlets pass through separate needle valves into the 6-port sample stream selector valve (Figure 1b, upper left), which is fitted with a 12-position actuator so that the valve can be turned off between ports. The outlet of the sample stream selector valve passes through a Nafion drier tube mounted inside a countercurrent flow of dry "zero air." The dried sample then passes first through a 6-port gas sampling valve (GSV) used for the CH4 analysis and second through a 10-port gas sampling valve fitted with two separate sample loops for the two separate ECD systems. The outlets of both gas sampling valves pass through isolation coils to separate the two gas sampling valves, and to prevent back mixing of any contaminants which might be present in the poorly flushed internal volumes of the downstream pressure sensing and control system. Finally, the sample stream passes through a flowmeter before exiting the sample module.

Figure 1. Flow scheme of the AGAGE GC/ECD/FID instrument. Multiport valves are fitted with purge housings which make use of the effluent purge gas from the precolumns in each system.

Shown in Figure 1a are a small pump and solenoid valve which are connected to the sample stream exit of the sample module. These are used to extend pressure-programmed calibration curves below ambient pressure or to analyze flask samples that are not pressurized. Care is taken through valve control and purging to avoid contamination of the samples or sample loops, especially contamination of one sample by another or contamination of the FID system by CH4 from the Ar-CH4 carrier gas used for the ECDs.

Not shown in Figure 1 is the configuration of the sampling systems at Cape Grim, Tasmania, and Mace Head, Ireland, where existing Trace Analytical MRDs were being used for independent analyses of H2 and CO. The AGAGE data acquisition and processing capabilities are used for H2 and CO also. However, the pressure-programming approach for nonlinearity corrections is not applicable to the MRD channel due to early elution for H2 and a large concentration range for CO. For these gases, extra standards covering a wider range are used. In addition, the normal AGAGE single-loop FID gas sampling valves at these two sites were replaced by dual-loop sampling valves of the type used for the ECD sampling. The column switching valves in the MRD instruments were also replumbed and rewired to be run by the AGAGE system's program control.

The pressure measurement and control system represents a major advance of AGAGE over ALE/GAGE. It consists of two thermostatted Barocel type 600 precision capacitance manometers which check each other and are verified using a Paroscientific precision quartz pressure standard. It is operated by an MKS model 146 programmable controller. This system allows the pressure of the flow-through sample inlet system to be programmed and measured, so that chromatographic nonlinearities can be determined by injecting varying amounts of a single standard. This approach requires that there be no concentration-dependent interference effects in the chromatographic measurements. This approach also requires that the subtle effects associated with changes in peak shape caused by varying the size of the injected sample, as opposed to varying the concentration of the injected sample, be addressed quantitatively. This includes distinguishing the differing effects of sample size and concentration on peak areas and heights including the fact that a detector that is nonlinear will be more nonlinear when peaks are quantified by height than when they are quantified by area. Although area measurements are generally preferred when the chromatographic separations are good, the occasional appearance of unresolved contamination peaks can interfere with the accurate determination of areas without seriously affecting height determinations. For this reason, AGAGE has the capability of working either with areas or heights.

The nonlinear effects discussed above have been quantified by comparing pressure programming analyses to constant pressure injections of primary standards covering a suitable range of trace gas concentrations. Corrections needed to convert between area-based and height-based nonlinearities are also well-characterized for the AGAGE instruments by measuring a range of primary standard concentrations. The advantages of programming injections of a single standard over a wide range of pressures, compared to the alternative of maintaining appropriate ranges of standards for each of the AGAGE species measured at each of the stations, are considerable. The chromatographic separation techniques used in the new AGAGE instrument are based on previous experience in GAGE and elsewhere, but in each case there have been changes to improve peak shape and/or long-term precision.

The FID CH4 measurement was adapted from the method used by Fraser et al. (1984) and Steele et al. (1987). The method uses a silica gel precolumn, separate backflush and sampling valves to provide independent control of the timing of each operation, a 5 Å molecular sieve column, and a sample loop volume of 10 mL.

The ECD channel which measures CCl3F, CCl2FCClF2, CHCl3, CH3CCl3, and CCl4 uses a silicone (SP2100) column similar to that used in GAGE, except that in AGAGE a better separation is obtained by using a 4.8 mm diameter column instead of a 6.4 mm column, by increasing the column length, and by raising the column temperature from 50°C to 55°C. A silicone precolumn has also been added to remove peaks which elute after CCl4. This reduces interferences with subsequent runs by sample or standard contaminants such as CHCl CCl2, and reduces uncertainties by allowing more rapid cycling between samples and standards (20 min in AGAGE versus 60 min in GAGE). The sample loop volume is 4.5 mL.

The ECD channel used to measure CCl2F2 and N2O incorporates an improved approach to the separations compared to GAGE. First, a 5 Å molecular sieve column (at 185°C) elutes CCl2F2 together with oxygen and nitrogen, but resolves N2O from these gases and from CO2. Then, after passage through a Porasil C column, the CCl2F2 peak elutes relatively low on the oxygen tail, and the N2O peak elutes after CCl2F2 and is much more clearly resolved compared to ALE/GAGE. CCl3F and heavier halocarbons are destroyed on the molecular sieve at this temperature so most late peaks are removed. A Porasil C precolumn is used nonetheless. The sample loop volume is 2 mL.

The entire instrument is under the control of Linux based PC using multiple RS-232c serial data ports and control software written at SIO. This includes all the electrically actuated Valco valves, the MKS model 146 pressure controller, the HP5890 GC, the Carle FID with an HP data acquisition system, and a Best uninterruptible power supply (UPS) for purposes of controlled instrument startup and shutdown in the event of extended power loss.